Next-gen technology:

Revolutionizing metal fabrication

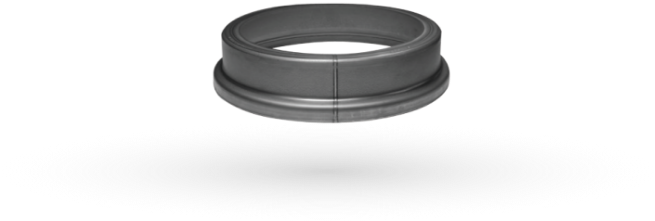

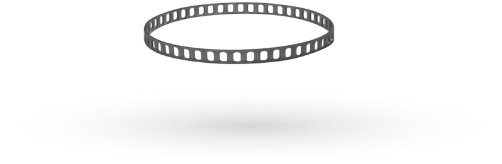

Inno-Spin automation and process innovation delivers round and cylindrical components at lower costs, greater efficiencies and better ROI.

Compelling benefits, precision performance

Inno-Spin maintains the dimensional and performance characteristics of stamped products while lowering costs, streamlining production and reducing your carbon footprint.

Proven across the most demanding applications

Products using Inno-Spin’s proprietary process are standing up to the harshest environments every day across freight rail, trucking, automotive and industrial applications.

FREIGHT RAIL | TRUCKING | AUTOMOTIVE | ELECTRIC VEHICLE | INDUSTRIAL

Made in the USA

Inno-Spin has a growing portfolio of high-reliability products to meet your needs. And every product is manufactured to the tightest tolerances at our New Jersey facility.

Backed by experience

Inno-Spin is a joint venture between companies with a long heritage of expertise in automation, process innovation and leading-edge engineering capabilities.

PRODUCT TESTING:

Seal cases manufactured using Inno-Spin™ process pass rigorous testing standards

It’s time to rethink stamping. Talk to an Inno-Spin expert today.